Description

Centralized vacuum supply systems for industrial production

Centralized vacuum supply systems for industrial applications from Baratti Engineering are planned, quoted and realized according the following major technical aspects:

- Contact free, oil-free, operating vacuum blowers/claws or screws depending on required vacuum level

- Minimum maintenace requirement für generating system as well as accessories

- Fully automatic vacuum control in reference to production demand for optimized power requirement

- Energy recovery of heated discharge air by reusing in the local energy network such as heating or air heating of warehouse in the plant

- Payback of investment in less than 24 months due to energy saving compared to previous solution

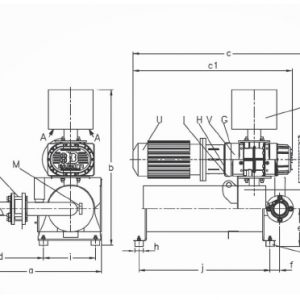

Depending on the production range we split the total demand into 33-25 or 20 % per machine and also we recommend a spare unit to back up 100 % production if one unit fails. Each pump has a turn down between 0 to 100 % by means of frequency inverter and pneumatic driven valves! Therefore we guarantee for the user a controlled supply between 0 to 100 % of his demanded capacity. The vacuum generating systems such as roots blower ATMOS, vacuum claw VKL or vacuum screw Stratos can be installed with or without super silent sound enclosure! Selection of the generating systems depends on the required vacuum level of the customer! In general, at a required vacuum level less than 100 mbar abs. we recommend two stage vacuum pump systems with booster to be more energy efficient. This will be used for food packaging and or medical evacuation of glassystems to analyse blood, where 20 mbar or less is required in the system!

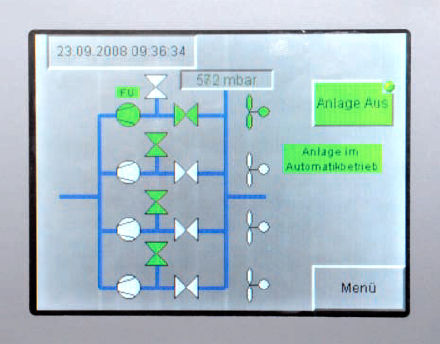

Centravaccontrol

The recently new developped Software for our „centravaccontrol“ panel provides the following major advantages fort the user:

- Ethernet connection for remote maintenace and function control from our factory

- Energy optimized control with frequency inverter and cut-in/cutt-off mode by pneumatic valves for all vacuum pumps!

- Automatic change over for sequence oft he pumps to achieve constant operating hours for all machines

- Display for history of errors and events

- Integrated maintenance plan according operating ours of pumps by means of warning signal at display

- P+I diagramm at display of touch panel

- Integrated leak test of central pipe system to check leakage rate of pipe system

- Multi language text at touchpanel display

These features provide the user a simple operation with a high comfort of operation.

Accessories filters with automatic jet cleaning

For applications with dust and or solid particles such as vacuum cleaning systems or pneumatic conveying systems, Baratti Engineering supplies high efficient mini bag filter systems with automatic jet cleaning. The installation of the filter within the central system is so, that the drain of dust in the dust reservoir can be done without an interruption of the whole system! Therefore isolation and venting valves are installed at the filters. We also recommend to install one filter for each vacuum pump to avoid production losses due to filter cartridge breakdown etc! The drainage of the dust reservoir is done manually eather by opening the bottom of the reservoir or by opening the 4″ drain access for a vacuum cleaner, to suck out the dust into the vacuum cleaner. In case you have a hazardous dust you have to use an ex proof vacuum cleaner to avoid any ignition!

Heat recovery

Due to the integrated heatrecovery your efficiency of the whole system becomes even more effective! Approx. 85 % of the required electrical power of the drive motor from the contact-and oilfree vacuum generating systems is transferred into the heated discharge air. Cooling of the discharge air down to suction temperature will gain 85 % of the previous required electric energy in form of heat. This can be realized by means of water-air heat exchanger to heat up the return of central heating or boilerwater. Or the hot discharge air is guided into different storage or production rooms to heat up those or keep it in a constant temperature range. The heat can also being used for recovery of air drying systems.

Scope of supply

Baratti Engineering is designing, is supplying components, if required we have supervisors for assembling at site or will assemble the system at site, will do the commissioning of the system as well as teaching maintenance and operator staff.

Applications

- Printing industry

- Envelope manufacturing

- Pneumatic conveying

- Central vacuum cleaning

- Medical vacuum suply for evacuating glass samples

- Food packaging

- Automatisation, vacuum handling, robots